The self-priming pump is a critical and versatile piece of equipment in fluid mechanics, designed to overcome a fundamental limitation of standard centrifugal pumps: the inability to pump air. In applications where the pump is situated above the liquid source (a suction lift condition), a conventional centrifugal pump requires manual pre-filling, or "priming," with liquid to create the necessary vacuum for operation. The self-priming pump eliminates this cumbersome requirement through ingenious design features, making it an indispensable tool across numerous industrial and municipal sectors.

1. Working Principle: The Mechanism of Automatic Priming

The defining characteristic of a self-priming pump is its ability to automatically evacuate air or gas from the suction line and pump casing, allowing atmospheric pressure to push the liquid up the suction pipe and into the impeller. This process typically occurs in two distinct phases:

A. Priming Mode (Air Evacuation)

-

Retention: The pump casing is designed with a reservoir or separation chamber that retains a fixed volume of liquid (usually from the previous run) even when the pump is turned off.

-

Air-Liquid Mixture: When the pump starts, the impeller begins to rotate, drawing a mixture of air (from the suction line) and the retained liquid from the reservoir into the impeller vanes.

-

Separation: The centrifugal force generated by the impeller accelerates this mixture. As the mixture exits the impeller and enters the specially shaped discharge casing (volute), the difference in density between the air and the liquid causes them to separate. The denser liquid is forced down into the reservoir, while the lighter air/gas is vented out through the discharge port.

-

Recirculation and Vacuum: The air-free liquid returns to the impeller eye to mix with more incoming air, creating a continuous loop. This recirculation process gradually evacuates all air from the suction line, creating a vacuum.

-

Lift Initiation: Once the suction line is fully evacuated of air and a sufficient vacuum is established, atmospheric pressure forces the process liquid up the suction line and into the pump.

B. Pumping Mode (Normal Operation)

Once the pump is fully primed with liquid, it transitions to its normal operational phase, functioning essentially as a standard centrifugal pump, efficiently transferring fluid. The retained liquid and separation chamber remain in place, ready for the next start-up.

2. Key Design Features and Types

While the core principle remains consistent, self-priming capabilities are integrated into different pump architectures:

-

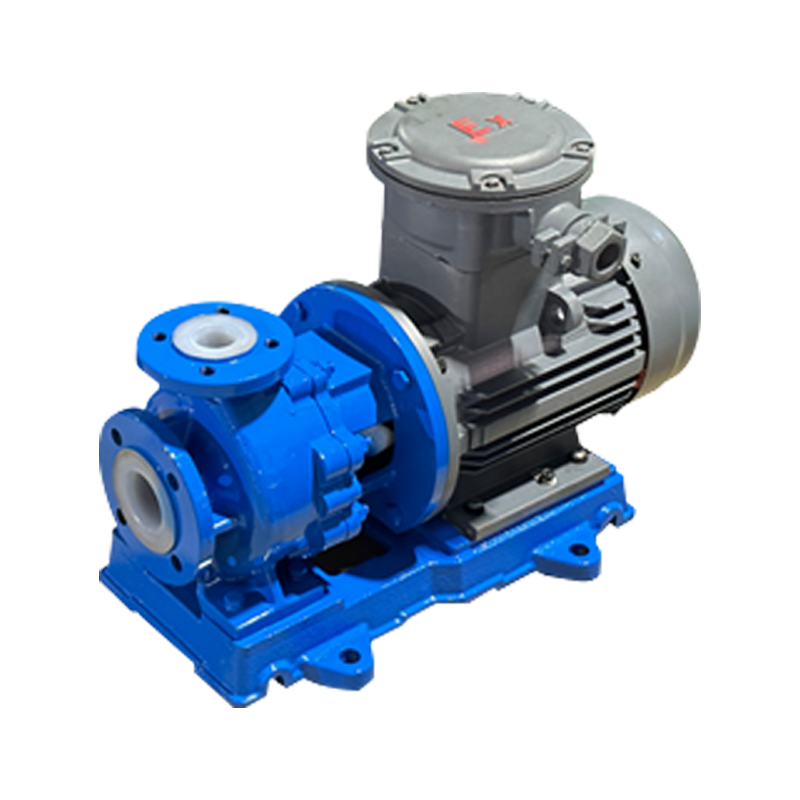

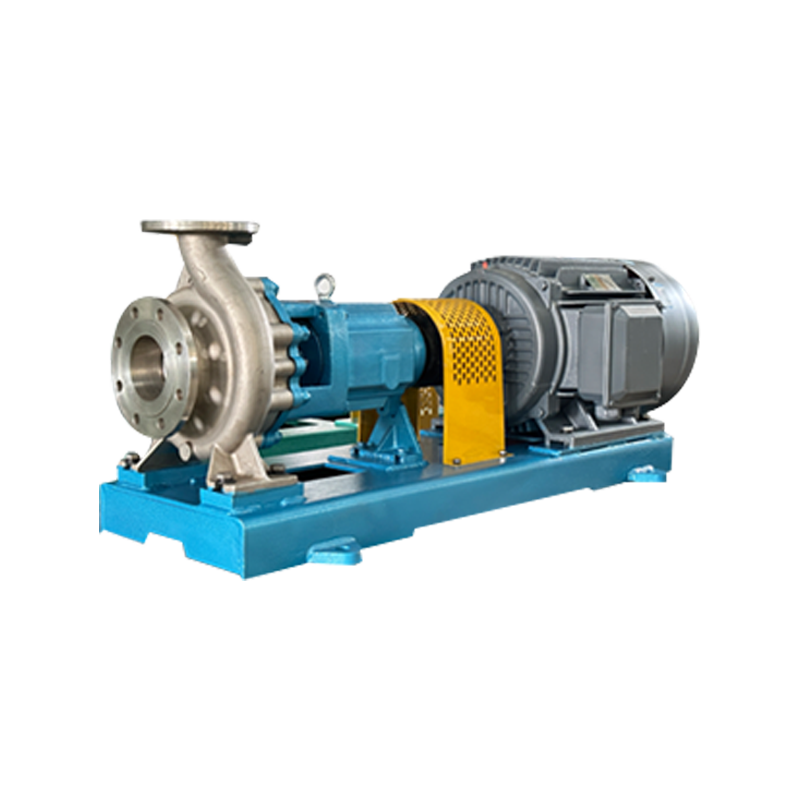

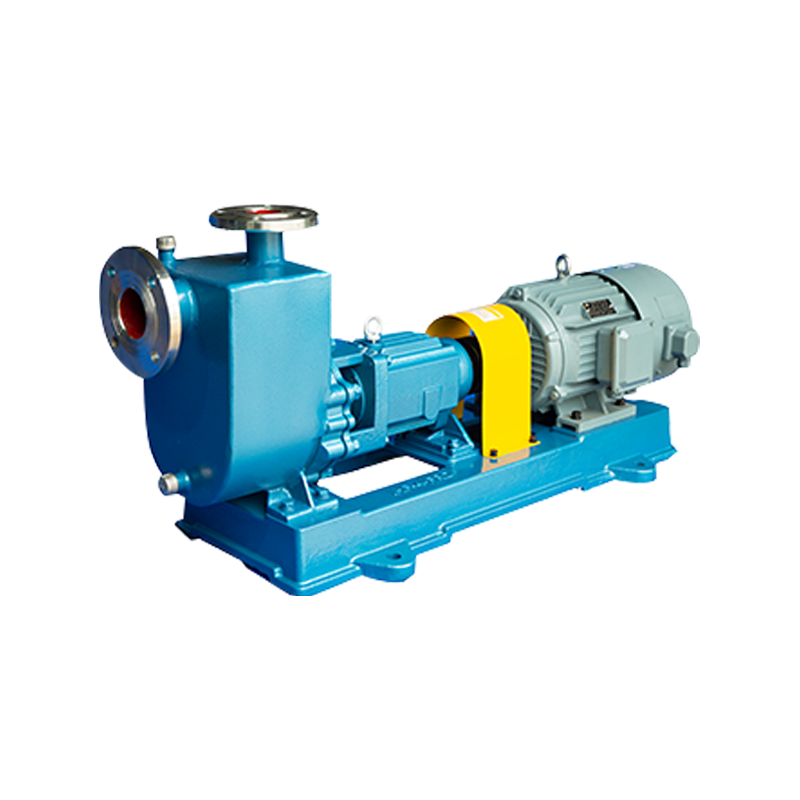

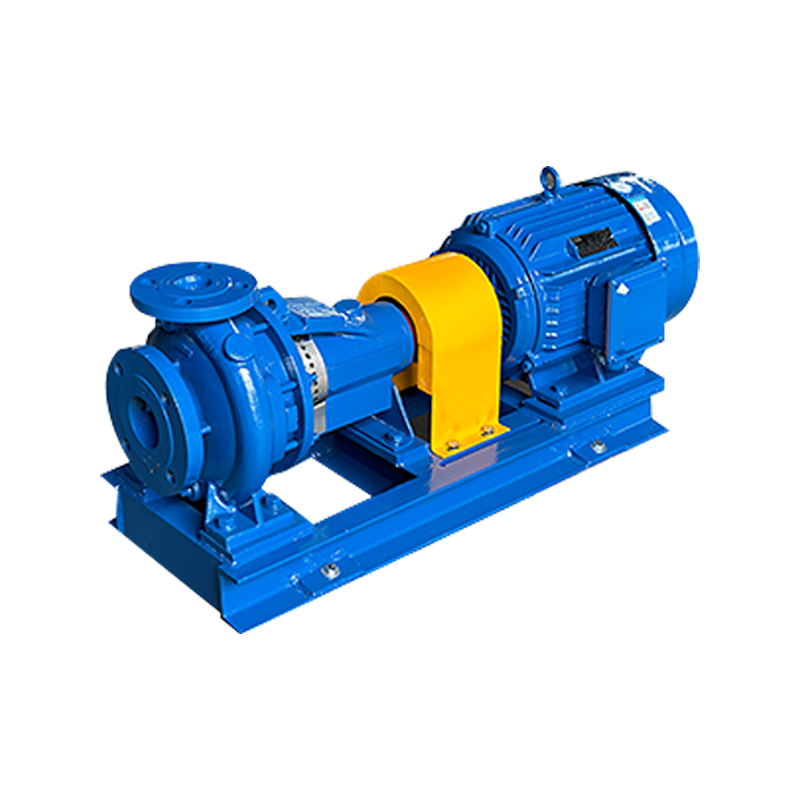

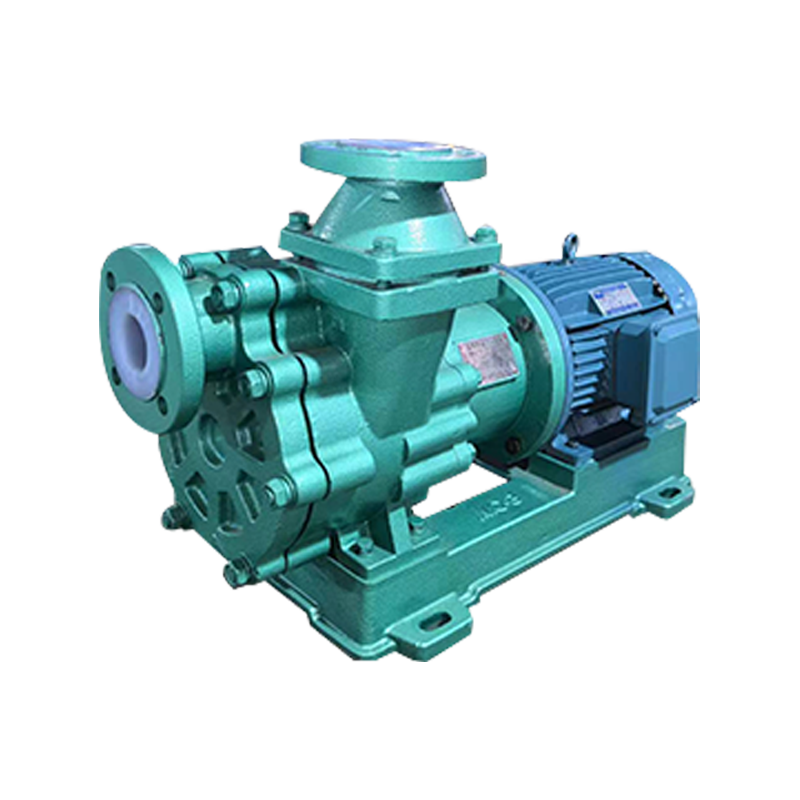

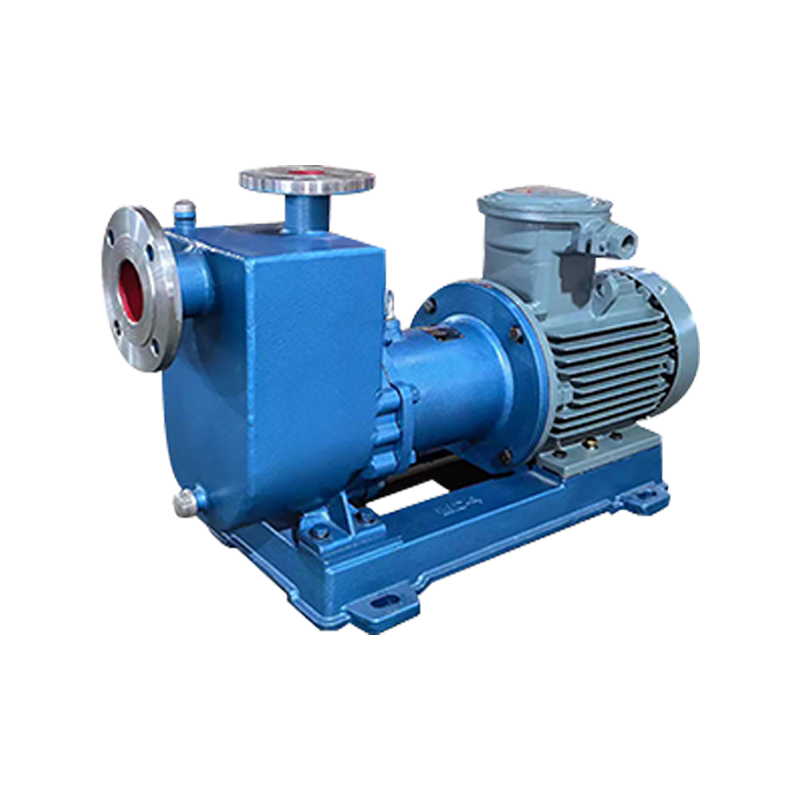

Self-Priming Centrifugal Pumps: These are the most common type. They are characterized by the large internal reservoir and volute/diffuser design that facilitates the air-liquid separation. They are excellent for handling moderate solids and slurries.

-

Positive Displacement Pumps (e.g., Diaphragm, Piston, Peristaltic): Many positive displacement pumps are inherently self-priming due to their tight internal clearances and operating principle, which allows them to effectively seal and create a vacuum even when handling air. They are often preferred for highly viscous fluids or precision dosing.

3. Advantages and Disadvantages

Choosing a self-priming pump involves weighing its functional benefits against certain performance trade-offs:

4. Common Applications

The unique benefits of automatic priming make these pumps essential in challenging environments:

-

Dewatering: Rapid removal of water from construction sites, mines, and excavation areas where the pump is often placed on dry ground above the water source.

-

Wastewater and Sewage: Pumping raw sewage or sludges, where the pump needs to be located at ground level for easy maintenance, and must be able to handle solids and gases.

-

Industrial Sumps: Emptying collection pits or sumps in processing plants where the liquid level fluctuates.

-

Tanker Offloading: Stripping fluid from the bottom of transport tankers, where the pump is located externally and needs to overcome air pockets.

-

Marine & Agriculture: Bilge pumping on vessels and transferring water from ditches, ponds, or irrigation canals.

In conclusion, the self-priming pump represents a significant leap in pumping technology, trading a minor reduction in hydraulic efficiency for a major gain in operational flexibility, reliability, and automation. Its design ensures hassle-free startup in suction lift conditions, cementing its status as the go-to solution for demanding fluid transfer applications.